Qingdao, China

Tel: +86-13793299898

Qingdao, China

Tel: +86-13793299898

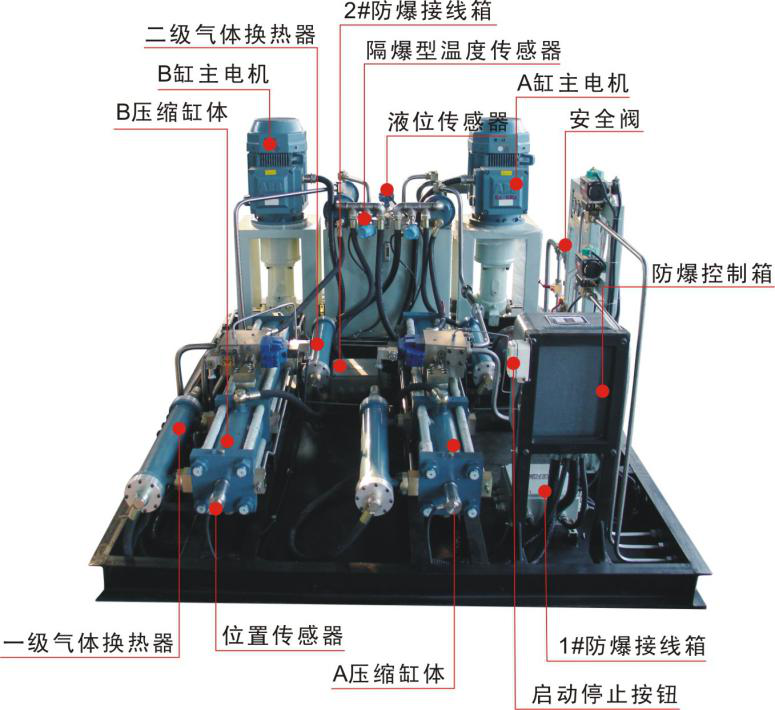

The hydraulic piston type sub-station compressor uses a motor to drive a hydraulic piston oil pump to drive the piston to reciprocate to compress natural gas. The design of the compressor cylinder is unique, adopting two-stage compression. Compared with the traditional single-stage compression, the oil pressure of the oil pump is low, so it has good stability and more power saving.

Like this product? Share it with your friends!

The hydraulic piston type sub-station compressor uses a motor to drive a hydraulic piston oil pump to drive the piston to reciprocate to compress natural gas. The design of the compressor cylinder is unique, adopting two-stage compression. Compared with the traditional single-stage compression, the oil pressure of the oil pump is low, so it has good stability and more power saving.

Compressor technical parameters:

CNG sub-station compressor model | LKCNGY700—1A | LKCNGY700—2C | LKCNGY1000-1B | LKCNGY1000-2C | |

Compressed media | natural gas | natural gas | natural gas | natural gas | |

Type | Skid-mounted | Skid-mounted | Skid-mounted | Skid-mounted | |

Drive method | Hydraulic piston drive | Hydraulic piston drive | Hydraulic piston drive | Hydraulic piston drive | |

Drive method | Oil-free lubrication | Oil-free lubrication | Oil-free lubrication | Oil-free lubrication | |

Average flow | Nm3/h | 700 | 1400 | 1000 | 2000 |

Control form | PLC automatic control | PLC automatic control | PLC automatic control | PLC automatic control | |

Inspiratory pressure | MPa | 3.0—20.0 | 3.0—20.0 | 3.0—20.0 | 3.0—20.0 |

Maximum exhaust pressure | MPa | 25.0 | 25.0 | 25.0 | 25.0 |

Suction temperature | ℃ | ≤45 | ≤45 | ≤45 | ≤45 |

Suction temperature | ℃ | <50 | <50 | <50 | <50 |

Rotating speed | r/min | 1450 | 1450 | 1450 | 1450 |

stroke | mm | 400 | 400 | 400 | 400 |

stroke | Level 2 | Level 2 | 二级 | 二级 | |

Dimensions | L×W×H mm | 2800×2000×1860 | 3900×2400×1860 | 2800×2000×1860 | 3900×2400×1860 |

noise | dB(A) | ≤70 | ≤70 | ≤70 | ≤70 |

rated power | KW | 30 | 30X2 | 37 | 37X2 |

According to the existing station construction (the construction of gas stations in urban areas has strict requirements for noise), our company can provide noise-reducing hydraulic piston compressors, and the test noise within 10 meters can be less than 55 dB(A).

2.1.5.2.2 Technical characteristics of hydraulic piston CNG sub-station compressor

1 The compressor adopts dual systems, which can be operated independently, and can guarantee uninterrupted work 24/7:

2 The operation of the hydraulic piston compressor gas station can achieve zero gas loss:

3 The compressor drive hydraulic oil consumption is small, and the operating cost is low:

4 The compressor cylinder piston adopts a patented oil-free lubricated sealing structure, which has no pollution to natural gas and has a very long life:

5 The mute protective box adopts the principle of resonance noise reduction, and the noise reduction effect is better:

6 Explosion-proof high-pressure solenoid valve replaces pneumatic ball valve, safer to use and more stable performance:

7 The compressor is equipped with a three-layer pressure safety protection system to ensure that the pressure is kept within the safe pressure range and the performance is safe and reliable:

8 The compressor can be operated continuously without adding lubricants:

9 The compressor does not need to be unloaded and is driven at any time, saving operating costs:

10 The compressor adopts PLC automatic control and remote control, which can realize remote diagnosis and management:

11 The use of general-purpose natural gas tank trucks is easy to operate and reduces equipment investment:

Compressor internal system