Qingdao, China

Tel: +86-13793299898

Qingdao, China

Tel: +86-13793299898

This equipment is mainly used for the manufacture of disposable masks. It adopts ultrasonic welding and photoelectric control technology, which can complete the welding of the mask body and ear straps at a time. The fully automated standardization process can greatly reduce labor costs, and effectively reduce manual contact during the production process to achieve aseptic standards, making it an ideal device for mask making.

Like this product? Share it with your friends!

Production mask specifications:

Standard type: 175*95mm (mask specification)

Equipment installation and configuration requirements:

(1) Equipment weight: ≤1500kg, ground load>300KG/e

(2) Working power: equipment 220V, 50z (customizable)

(3) Compressed air: 0.5″0.7MPa, use flow rate about 300L/min

(4) Operating environment: temperature 1035℃, humidity 5-35% HR, no flammability, corrosive gas, no powder (cleanliness is not less than 100,000).

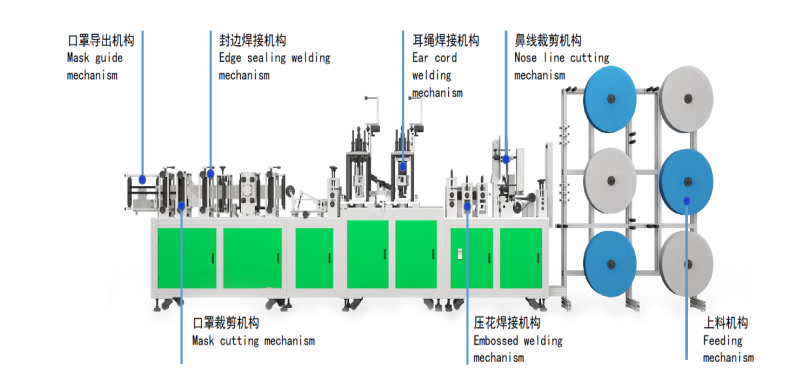

Equipment Overview:

This equipment is mainly used for the manufacture of disposable masks. It adopts ultrasonic welding and photoelectric control technology. It can complete the welding of the mask body and ear straps at a time. The dual-channel structure. The fully automated standardization process can greatly reduce labor costs, and effectively reduce manual contact during the production process to achieve aseptic standards, making it an ideal device for mask making.

Production Process:

1. Multi-station non-woven fabric unloading----->roller transmission----->folding of mask body----->placement of nose bridge----->ultrasonic edge banding---- ->Mouth mask body molding----->Diversion-----> Ear strap welding----->Automatic stacking

2. After unwinding the entire roll of fabric, it is driven by a roller, and the fabric passes through automatic folding and wrapping;

3.The nose bridge is pulled and unwound in a full roll, cut into a fixed length and then introduced into the edging fabric, the two sides are ultrasonically welded to the seal, and then the ultrasonic lateral seal is cut and formed by the cutter

4. The mask is transported to two mask ear strap welding stations through the assembly line, and the final mask is formed by ultrasonic welding. After the mask is made, it is transported to the flat belt line for collection through the assembly line.