Qingdao, China

Tel: +86-13793299898

Qingdao, China

Tel: +86-13793299898

CNG standard station is compressing and pressuring CNG from natural gas pipeline and fueling to NGV or to storage bottle groups. It consists of metering & pressure regulating equipment, desulfurizing and dewatering equipment, natural gas compressor, CNG storage equipment, priority panel, CNG filling equipment, safety protection equipment, electrical equipment, CNG pipelines and accessories etc.

Like this product? Share it with your friends!

CNG standard station is compressing and pressuring CNG from natural gas pipeline and fueling to NGV or to storage bottle groups. It consists of metering & pressure regulating equipment, desulfurizing and dewatering equipment, natural gas compressor, CNG storage equipment, priority panel, CNG filling equipment, safety protection equipment, electrical equipment, CNG pipelines and accessories etc.

CNG mother station mainly fuels CNG to high-pressure tube trailer. The process system is the same as the standard station, the main difference is that the discharge capacity of mother station compressor is larger, and the capacity of storage bottle groups is larger.

Luke provides suitable compressors for mother stations and standard stations matching different parameters requirement and we provide service including gas stations design, engineering installation, commissioning and technical training etc.

The models are manufactured by both Luke and LMF. The main important parts, such as cylinders, seals and so on, are imported from German and Austria. Through joint development we have obtained the most advanced Germany technology, anddeveloped compressors with high performance according to Chinese standard to meet domestic need.

Technical Characteristics of Standard /Mother Station compressor:

●The vulnerable parts( e.g. air valves, piston rods ) are imported from Austria HOERBIGER, the service life of spare parts can last more than 8000 hours.

●Since the engine adopts soft starter, it allows the compressor start and stop frequently.

●The compressor is designed to accept a wide range of inlet pressure, it can be used to compress natural gas at different pressures.

●The compressor is a skid structure, simple but compact design, so it is easy to be installed. The panels are noise-proofing material, so it will protect the noise from spreading out, and make a quiet environment around the compressor.

●The controlling system is SIEMENS PLC control system which is highly automatic level and free from operation. Furthermore, compressor mount-skid is equipped with a large amount of sensors responsible for pressure control, temperature control and gas leaking detect. It can ensure the machine running safe for a long time.

●Using point to point low-oil lubrication, reduce oil supply based on ensuring the lubrication effect, not only to improve the seal life, but also to save the amount of lubricating oil.

●Use high quality packing seal, to prevent the cylinder gas leakage, to ensure the safety of overall equipment.

●Gas connecting pipe of compressor is made of welded pipe. It is more safe and reliable compared to the traditional connection mode.

●Compressor adopts the integral modular design, the maintenance is convenient to assemble and disassemble, and ensure the equipment running time and efficiency.

●Using the method of water circulation and air cooling, the initial temperature of the compressor gas is reduced, and compression efficiency is improved.

●By controlling assembly process, equipment vibration is much smaller than foreign products. It can prevent a series of hazards caused by vibration.

●The whole equipment is equipped with automatic sewage system, no need of manual, timing and automatic sewage, save manpower, improve equipment efficiency.

●Through the reasonable compression ratio design, compressor uses the multistage compression. Capacity and efficiency are the highest compared with the similar equipment.

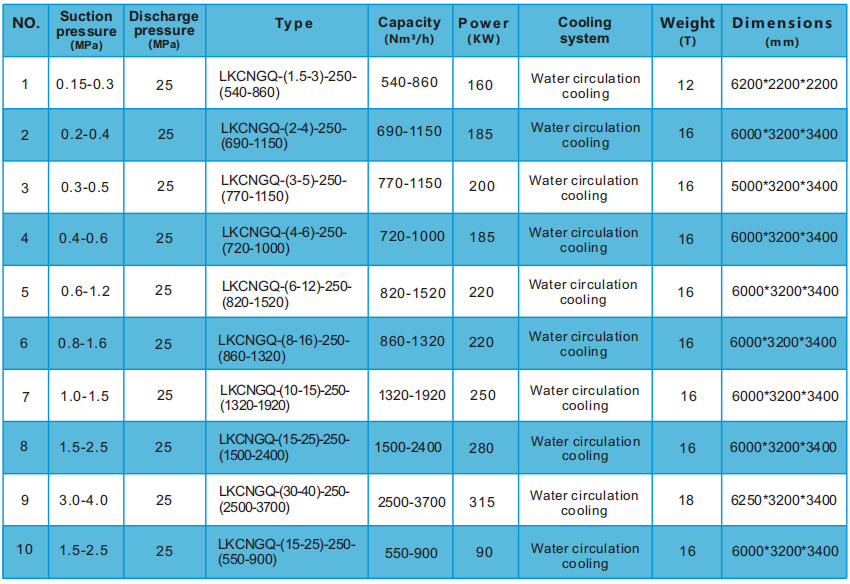

LUKE could provide suitable compressors for mother station and standard station, matching different parameters requirement due to natural gas pipeline, such as suction pressure and capacity. Parts of models as below :